Lightweight design is one of the most prominent requirements of almost all types of vehicles these days. Lightweight is the key driver when it comes to reducing the energy or fuel consumption of vehicles.

Design approaches for lightweight automotive parts, procedures using materials istanbul escort with great explicit properties, and hybrid materials are also being utilized by the top sheet metal components manufacturers in India to boost the performance of parts of different vehicles, especially cars.

If you are driving a heavy-duty vehicle such as heavy trucks or body-on-frame SUVs, you might be wonderstruck that a lightweight vehicle can change your driving experience for all the positive reasons. Cutting down on heavy metals such as stainless steel, is one of the primary mottos of all the leading sheet metal components manufacturers in India and across the globe.

This article discusses some of the top advantages of the lightweight vehicle in the following points:

-

Material savings and minimized environmental footprint

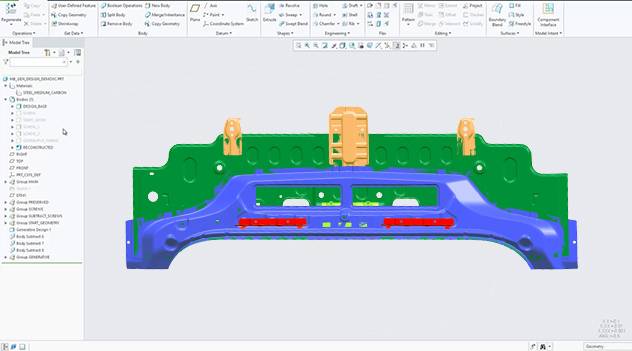

Lighter automotive components made and supplied by the leading sheet metal components manufacturers in India involve reduced materials costs when compared to their heavy counterparts. They also call for lesser energy during the manufacturing process. And, when material consumption is reduce, the carbon footprints also get lowered. Generative design and topology optimization methodology in automotive components manufacturing also provide a large number of ways to achieve lightweight parameters when practiced with additive manufacturing.

-

Greater fuel efficiency

While lighter parts or components are always desire most in the field of engineering, they are also not less valuable when it comes to the manufacturing of automobiles. Even a moderate reduction of weight by 10% can engender a boost in fuel efficiency by 6-8%. Aerospace manufacturers also take advantage of light components. All this calls for intelligent and farsighted manufacturing methodologies through which reduced materials are use to manufacture different types of auto components.

-

Enhanced Safety

There is a misconception that lightweight vehicles are not as safe as big vehicles are. As a result, people generally consider the heavy vehicle as part of the safety parameters. But, these are now the things of the past. With the rapid advancement in manufacturing technologies and the blends of different metals, a new era of lightweight and safe vehicles has begun.

Auto components manufacturers and suppliers across the globe are making use of innovative materials that are compose of the following:

- Carbon-fiber composites

- Aluminum

- Magnesium, and

- Steel blends.

All these innovative materials have allowed engineers and manufacturers the world over to bring down the overall weight of the vehicles with no compromise on strength, quality, durability, and reliability at all.

Improved overall performance

Lightweight vehicles equipe with light parts are not only rugg on performance but also more efficient than their heavy counterparts. The overall performance, efficiency, and power that you find in lightweight vehicles are not possible in heavy models at all. The vehicles having parts make of heavy metals such as stainless steel and others might seem to be solid and robust behind the wheel, but at the same time, they can also give you a clunky and awkward feel while steering and pulling the vehicle into the parking lots that are running short on space.

On the other hand, with a lightweight vehicle, you don’t have to face any such problems. Modern cars, trucks, and SUVs that are equipped with innovatively manufactured lightweight auto components are more maneuverable than ever, permitting the drivers to whip across tight spaces.

Concluding Remarks

SAN Automotive is one of the leading sheet metal components manufacturers in India offering a wide range of products for a wide range of industries. Delivering excellence through enterprise for the past 20 years, SAN Automotive is a well-diversified, multi-location, and multi-product Indian conglomerate located in the industrial hub of Faridabad (NCR).